The valve spring of the mud pump valve body determines the opening pressure of the valve, the valve flap stroke and the stability of the seal in the closed state. If these springs fail, the entire valve will not work properly. On this basis, the reasons for the failure of the valve spring are summarized…

Factors Causing Mud Pump Bearing to Burn out

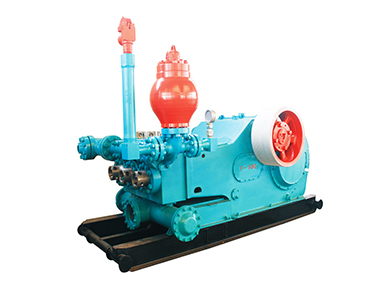

The drilling mud pump bearing is an important component to ensure the normal operation of the mud pump. It is one of the main accessories to ensure the power output of the mud pump. Although the parts of the mud pump accessories are small, they have a great effect. Therefore, the research on the mud…

What Should Be Paid Attention to when Maintaining Vacuum Pump and Mud Pump

The main purpose of the mud pump is to transport the industrial sector of pulp and pulp to produce wear-resistant slurry pumps, such as metallurgy, electric power, coal, mining and other industries are inseparable from its application. Its working characteristics are multi-slurry process and various non-solid particles, we need to know more about its use…

Reasonable and Scientific Maintenance of the Mud Pump Accessories

Many enterprise users can reflect that the maintenance and management of mud pumps are not complete. So how do we develop to maintain the mud pump scientifically? In fact, during the operation of the mud pump, the following issues should be paid attention to in time: whether the bearings of the mud pump accessories are…

What Is the Material Classification of Piston – One of the Mud Pump Accessories

Material classification of mud pump accessories (piston): 1. Nitrile rubber It is suitable for ordinary drilling environments where the working pressure is lower than 20MPa and the working temperature is not higher than 120℃. The nitrile rubber of the mud pump accessories has excellent wear resistance, chemical resistance and long service life in ordinary drilling…

Characteristics and Application of Horizontal Pump

The horizontal pump uses the high-speed rotating impeller blades to drive the water to rotate and throw the water out to achieve the purpose of transportation. There are many types of horizontal centrifugal pumps, which can be divided into civil and industrial pumps in use; in terms of conveying media, they can be divided into…

Roller Bearing Types and Characteristics

Ⅰ. Roller bearings Roller bearing is a kind of rolling bearing, and it is one of the parts widely used in modern machinery. It relies on the rolling contact between the main components to support the rotating parts. Roller bearings are now mostly standardized. Roller bearings have the advantages of small starting torque, high rotation…

The difference Between High-speed Bearing and Ordinary Bearing

High-speed bearings require precise dynamic balance of the rotating system where the bearing is located, and the shaft and seat hole where the bearing is installed should have dimensional accuracy and shape and position accuracy higher than the general requirements. The shaft support system requires both high rigidity and light weight as much as possible.…

The Difference Between Centrifugal Pump and Submersible Pump

Centrifugal pump is a kind of water pump classification. It is collectively called vane pump with axial flow pump, mixed flow pump, and vortex pump. There are also positive displacement pumps, jet pumps, etc., while submersible pumps should be one of the centrifugal pumps. They rely on the centrifugal force generated by the rotation of…

How to select hammer head coupling

The coupling is used to connect the shaft and the shaft so that they can rotate together and transmit torque. The two shafts connected by a coupling can only be separated after being disassembled after parking. When choosing a coupling, it is necessary to select a suitable coupling according to the type and characteristics of…